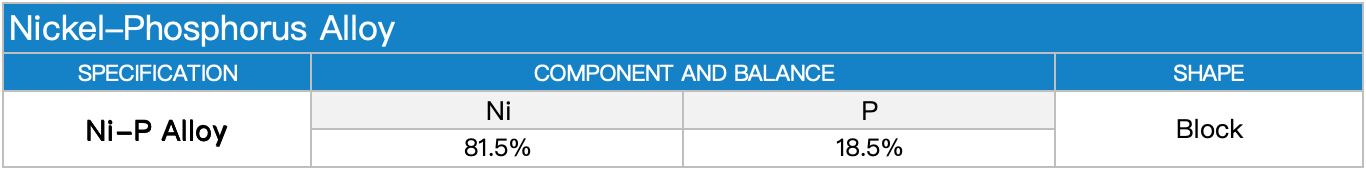

Nickel-phosphorus alloy

Classification: Nickel-Phosphorus Alloy

Features:

-

Corrosion Resistance: Excellent performance in acidic, alkaline, and salt spray environments, particularly superior to stainless steel in Cl⁻-containing media. Ideal for marine and chemical environments.

-

High Hardness & Wear Resistance: As-plated hardness of ~500-600 HV; increases to over 1000 HV after heat treatment (300-400°C), suitable for high-wear components.

-

Uniform Coating: Electroless plating ensures even coverage on complex geometries without additional machining.

-

Non-Magnetic (High Phosphorus Type): Non-magnetic when phosphorus content exceeds 10%, suitable for electronic devices. Note: Heat treatment may precipitate magnetic phases, requiring process control.

-

Weldability & Thermal Conductivity: Good welding performance and thermal conductivity, ideal for heat-dissipating components.

-

Catalytic Activity: High specific surface area and reactivity, used in hydrogenation, fuel cells, and catalytic reactions.

-

Thermal Stability: Oxidation-resistant at high temperatures; some grades withstand temperatures above 400°C.

Applications:

-

Anti-Corrosion Coatings:

-

Petrochemical: Corrosion protection for pipelines, valves.

-

Marine Engineering: Ship components, offshore platforms.

-

-

Electronics & Semiconductors:

-

Hard disks/connectors: Non-magnetic coatings.

-

PCBs/MEMS: Enhanced wear resistance and conductivity.

-

-

Mechanical Industry:

-

Bearings/gears: Extended lifespan.

-

Automotive: Wear-resistant treatment for pistons, fuel injectors.

-

-

Aerospace: High-temperature protection for engine components, turbine blades.

-

Catalysis: Catalyst supports, electrodes for water electrolysis hydrogen production.

-

Medical Devices: Corrosion-resistant coatings for surgical tools, implants.

-

Emerging Technologies:

-

3D Printing: Wear-resistant component manufacturing.

-

Composites: Enhanced matrix properties.

-

Packaging: Custom packaging

Shape: Block

Related products

No data