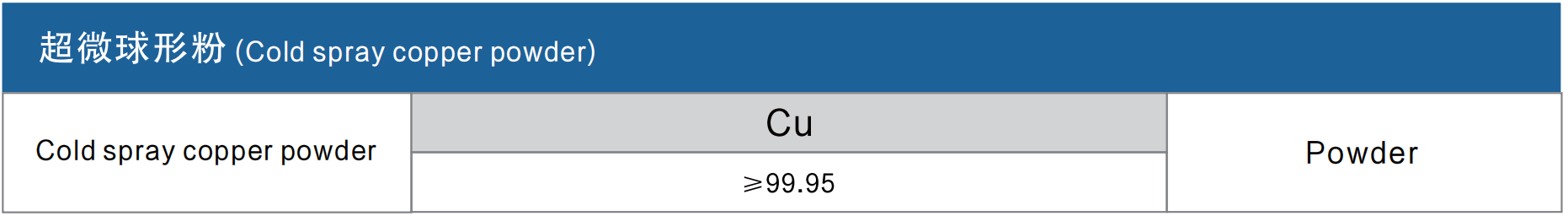

Cold Spray Copper Powder

Characteristics:

High Purity and Uniform Particle Size

- Purity typically exceeds 99.9%, with extremely low impurity content (e.g., Fe, Pb, As ≤0.001%).

- Narrow particle size distribution, with average particle sizes ranging from 50 nm to several microns. Customized production is supported to meet diverse application requirements.

Spherical Structure and High Dispersibility

- Particles exhibit high sphericity or near-spherical shape with smooth surfaces and excellent flowability, facilitating uniform dispersion in slurries and coatings to avoid agglomeration.

- Special surface activation treatment enhances bonding in composite materials, suitable for high-precision coating preparation.

Excellent Electrical and Thermal Conductivity

- The copper core provides high electrical conductivity, while outer silver coating (in selected models) further improves oxidation resistance, making it suitable for high-frequency circuits and electromagnetic shielding materials.

- Outstanding thermal conductivity applies to heat dissipation materials, lubricant additives, etc., optimizing equipment thermal management efficiency.

Chemical Stability and Weather Resistance

- Oxidation and corrosion resistant, suitable for high-temperature, high-humidity, and acid-base environments, maintaining stable performance after long-term air exposure.

- Some products adopt silver-coated copper structures (e.g., micron silver-coated copper powder) to further reduce oxidation risks and extend service life.

Low-Temperature Sintering Characteristics

- Melting point of ultrafine particles is significantly reduced (e.g., melting point of nanoscale silver powder can be below 100°C), suitable for low-temperature sintering processes to minimize thermal damage to substrates and expand applications in plastic-based electronic components.

Applications:

Electronics and Semiconductor Fields

- Conductive Slurries and Coatings: Used for conductive layers in printed circuit boards (PCBs), multi-layer ceramic capacitor terminals, and flexible printed circuit boards (FPCBs) to enhance signal transmission efficiency.

- Electromagnetic Shielding Materials: Made into coatings or patches to suppress electromagnetic interference (EMI) in electronic devices and enhance signal stability.

Energy Sector

- New Energy Batteries: Applied in electrode materials and thermal management systems to improve charge-discharge efficiency and heat dissipation performance of lithium-ion batteries.

Packaging:Iron drums, pallets, customized packaging

SHAPE: Powder

Special particle size distribution suitable for cold spray processes in communication transmission lines and automotive components.

Specifics of Cold Spray Process:

The cold spray technology forms dense coatings by propelling ultrafine spherical copper powder onto substrate surfaces at high speed, offering advantages including:

- Low-Temperature Processing: Avoids thermal deformation of substrates, suitable for sensitive materials like plastics and composites.

- High Coating Density: Particles undergo plastic deformation upon impact, reducing porosity and enhancing corrosion resistance and electrical conductivity.