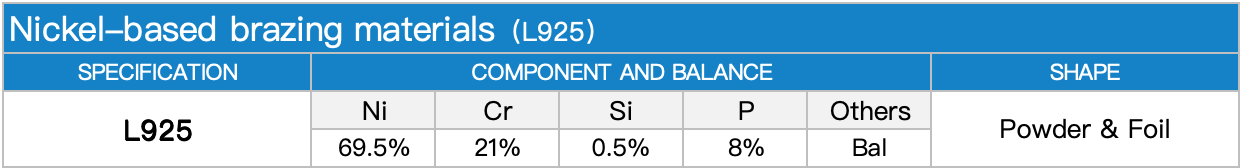

Nickel-based brazing material L925

Suitable for brazing stainless steel and high-temperature alloy components, such as EGR coolers and heat exchangers in automotive engines. The higher phosphorus content gives it a lower melting point, which can avoid the non-melting phenomenon of brazing filler metal caused by poor furnace tightness or too short brazing time.

Share

Describe

Powder