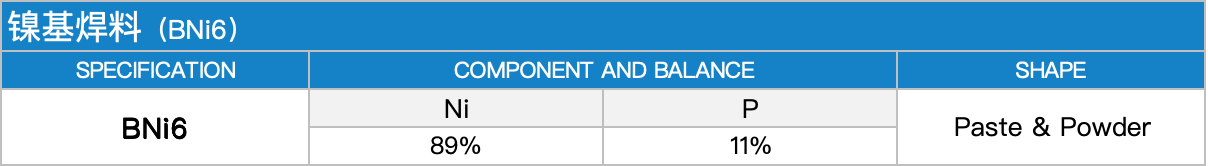

Nickel-based brazing materials BNi6

Product Features:

1. Exceptional High-Temperature Performance: Braze joints withstand temperatures exceeding 1000°C, with superior oxidation resistance and thermal fatigue resistance.

2. Excellent Flowability: Low melting point (liquidus ~1050°C), strong wetting ability, and void-free dense weld seams.

3. Versatile Forms: Available in 10-50μm fine powder (compatible with automated powder feeding/preplacement processes) and easy-to-apply paste.

4. Broad Compatibility: Suitable for joining stainless steel, high-temperature alloys, hard alloys, and dissimilar metals.

Application Fields:

-

Aerospace: Repair brazing of engine combustion chambers and turbine blades.

-

Nuclear Energy: Seal welding for heat exchangers and high-temperature valves.

-

Electronics: Joining vacuum devices and semiconductor packaging.

-

Industrial: Hard alloy brazing for cutting tools and wear-resistant components.

Packaging: Steel drums; plastic drums; plastic bags; pallets & customized packaging.

Shape: Paste, powder & foil.