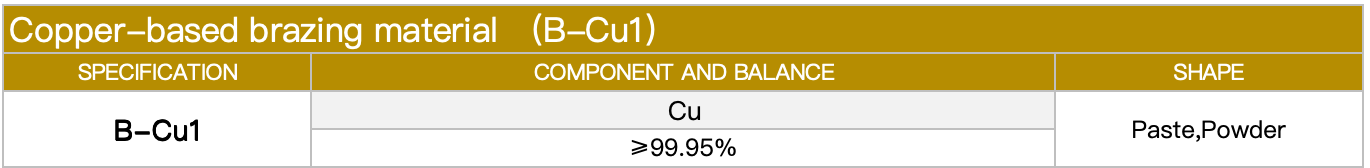

Copper-based brazing material B-Cu1

Classification: B-Cu1

Product Features:

-

High Electrical & Thermal Conductivity: Copper inherently offers excellent electrical and thermal conductivity. B-Cu1 ensures welded joints with superior conductive performance, meeting demanding requirements in electronics and high-efficiency thermal applications.

-

High Strength: Forms robust welded joints with strong mechanical stability, capable of withstanding external forces and vibrations, ideal for applications requiring reliable structural integrity.

-

Good Wettability: Exhibits excellent wetting behavior on most metal surfaces during welding, ensuring effective spreading and gap filling for high-quality joints.

-

Corrosion Resistance: Resists degradation in typical service environments, maintaining joint performance and extending product lifespan.

Applications:

-

Electronics Industry:

-

Soldering electronic components such as PCB pin connections and integrated circuit packaging, ensuring stable signal transmission and reliable electrical contacts.

-

-

Electrical Equipment Manufacturing:

-

Joining wires, windings, and components in transformers, motors, and relays, where high strength and thermal conductivity enhance electrical performance and heat dissipation.

-

-

Refrigeration Industry:

-

Connecting copper tubing in air conditioners, refrigerators, and cooling systems, providing corrosion resistance and strength to ensure system sealing and prevent refrigerant leakage.

-

-

Machinery Manufacturing:

-

Welding and repairing mechanical parts (e.g., tooling, structural components), where high-strength joints endure operational stresses.

-

Packaging: Iron drums, plastic drums, pallets, custom packaging

Shape: Paste & Powder

Note: Suitable forstainless steel, carbon steel, and cast iron. Delivers high joint strength with no post-weld residue.

Powder

Paste