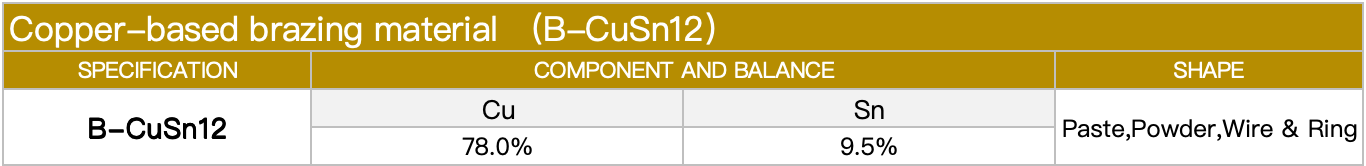

Copper-based brazing material B-CuSn12

Classification: B-CuSn12

Product Features:

-

Good Wettability: Effectively wets base materials (e.g., copper, copper alloys, and some stainless steels) during welding, ensuring high-quality joints with strong metallurgical bonding.

-

High Strength: Welded joints exhibit high mechanical strength, meeting structural requirements for load-bearing and vibration resistance.

-

Corrosion Resistance: Demonstrates excellent resistance to atmospheric, freshwater, and mildly corrosive environments, ensuring long-term stability of joints in service conditions.

-

Moderate Fluidity: Offers balanced flowability at brazing temperatures, filling joint gaps effectively without excessive spreading, enabling precise weld formation.

Applications:

-

Machinery Manufacturing:

-

Used for wear-resistant components such as bearings, bushings, gears, and worm gears. Combines wear resistance, high strength, and friction-reducing properties to withstand high loads and moderate sliding speeds, extending component lifespan.

-

-

Shipbuilding:

-

Ideal for marine valves, pump bodies, offshore platform fasteners, and hull structures due to excellent seawater corrosion resistance, ensuring durability in harsh marine environments.

-

-

Chemical Equipment:

-

Suitable for valves, pumps, and other components in corrosive chemical environments, resisting chemical media to maintain operational safety.

-

-

Electrical Engineering:

-

Applied in low-voltage electrical components (e.g., relay spring contacts) requiring balanced conductivity, strength, and corrosion resistance.

-

Packaging: Iron drums, plastic drums, pallets, custom packaging

Shape: Paste, powder, wire, welding rings.

Note: Used for copper-to-copper brazing.

B-CuSn12, leveraging its self-fluxing capability and superior wettability, serves as an efficient and cost-effective solution in electronics, refrigeration, and hard alloy welding applications.

Paste