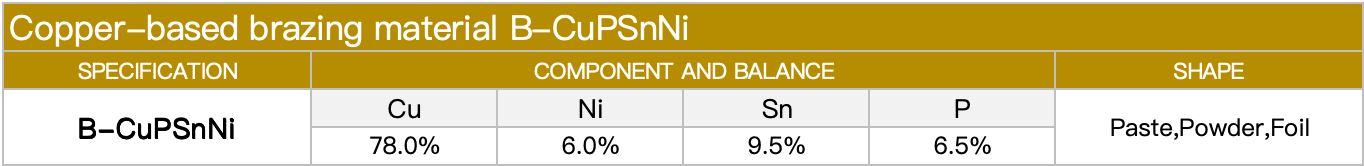

Copper-based brazing material B-CuPSnNi

Classification: B-CuPSnNi

Product Features:

-

Good Fluidity: A low-temperature brazing material in the copper-phosphorus series, exhibiting excellent flowability at brazing temperatures. Suitable for tight-fitting joints, it fills narrow gaps effectively to form full and aesthetically pleasing braze seams.

-

Self-Fluxing Property: Self-fluxing when brazing pure copper, eliminating the need for additional flux. This simplifies the welding process, improves efficiency, and avoids issues caused by flux residue.

-

Cost-Effectiveness: Lower cost compared to silver-based brazing materials, reducing production expenses.

-

Corrosion Resistance: Brazed joints offer corrosion resistance comparable to copper, maintaining performance in mildly corrosive environments.

Applications:

-

Electrical Contact Manufacturing: Ideal for brazing copper to silver and its alloys, ensuring high electrical conductivity and reliable connections in electrical contact products.

-

Copper Joint Welding: Widely used for welding copper joints in piping systems, electrical connections, and other applications requiring strong, sealed joints.

-

Copper Radiator Brazing: Suitable for atmosphere furnace brazing of pure copper components (e.g., copper radiators), enhancing performance and reliability.

Packaging: Iron drums, plastic drums, pallets, custom packaging

Shape: Paste, powder, foil.

B-CuPSnNi, leveraging its self-fluxing property and high wettability, serves as an efficient and cost-effective alternative in electronics, refrigeration, and hard alloy welding applications.

Paste

Powder