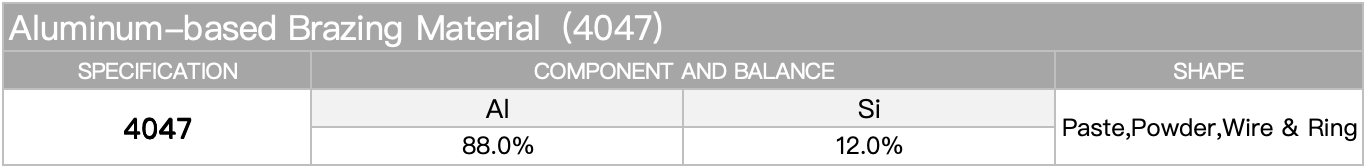

Aluminum-based Brazing Material(4047)

Classification: 4047

Product Features:

-

Low Melting Point: A eutectic aluminum-silicon brazing alloy with a solidus-liquidus range of approximately 577-582°C, enabling brazing at relatively low temperatures to minimize thermal impact on base materials and reduce deformation.

-

Excellent Fluidity: Silicon content (11.0-13.0%) ensures superior fluidity at brazing temperatures, allowing effective spreading on base material surfaces and gap filling to form full, dense braze joints.

-

High Strength: Welded joints exhibit tensile strength of 130-160 MPa, capable of withstanding external forces and vibrations.

-

Corrosion Resistance: Demonstrates strong resistance to atmospheric and aqueous corrosion, ensuring long-term stability of brazed joints.

-

Color Characteristics: Anodizes to a gray-black color; caution required for applications with strict aesthetic requirements.

Applications:

-

Automotive Manufacturing:

-

Brazing automotive radiators, fuel tanks, HVAC pipelines, and aluminum die-cast components, especially suitable for precision welding of thin aluminum parts.

-

-

Refrigeration & HVAC Industry:

-

Condensers, evaporators, and refrigeration fittings, ensuring sealing integrity and thermal conductivity.

-

-

Aerospace & Electronics:

-

Aerospace fixtures, electronic heat sink substrates, balancing lightweight design and high-temperature stability.

-

-

Marine Engineering & Shipbuilding:

-

Welding seawater pumps, propellers, and other components resistant to seawater corrosion and high-pressure environments.

-

-

New Energy & Power Equipment:

-

Electric vehicle battery module connections and high-voltage inverter heat dissipation components, ensuring thermal stability.

-

Packaging: Iron drums, plastic drums, pallets, custom packaging

Shape: Paste form, powder form, wire, welding rings

Composition & Balance:

-

Note: Eutectic Al-Si material with a melting temperature of ~580°C; can be strengthened through modification and soaking treatments.

Aluminum-based brazing material 4047, with its low melting point, high fluidity, crack resistance, and corrosion resistance, is widely used in automotive, refrigeration, aerospace, and other fields. As demand for dissimilar material welding grows, its potential in composite structure joining will further expand.