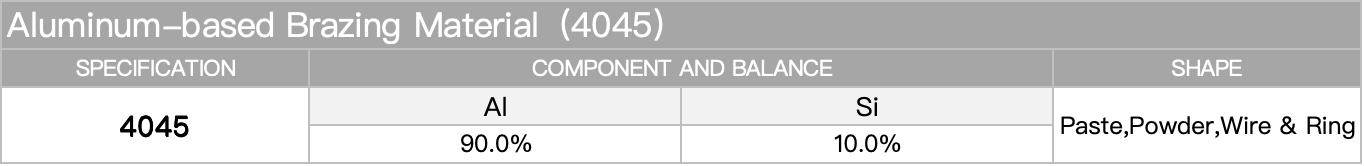

Aluminum-based solder 4045

Classification: 4045

Product Features:

-

Low Melting Point: Silicon content typically ranges from 10%-12%. The high silicon content lowers the melting point, enabling brazing at reduced temperatures to minimize impact on base material properties and thermal deformation.

-

Excellent Fluidity:

-

Powder particles are spherical with high sphericity, low surface oxygen content, uniform particle size distribution, high tap density, and no impurities.

-

Precise chemical composition ensures superior fluidity in powder, paste, or brazing paste forms during brazing, allowing effective spreading on base material surfaces and gap filling to form full, dense braze joints.

-

-

High Corrosion Resistance: Demonstrates exceptional resistance to common corrosive media, including atmospheric and aqueous environments, ensuring long-term stability of brazed joints.

-

High Strength: Brazed joints exhibit high mechanical strength, capable of withstanding external forces and vibrations, meeting the requirements for structural components.

Applications:

-

Automotive & Refrigeration Industry:

-

Brazing of automotive radiators, HVAC pipelines, and evaporators to enhance heat exchange efficiency through high thermal conductivity and sealing.

-

Precision welding for refrigeration compressor components to reduce leakage risks.

-

-

Electronics & Semiconductor Packaging:

-

Heat sink substrate welding for high-power electronic components (e.g., IGBT modules); nano brazing paste reduces thermal resistance and improves reliability.

-

-

Aerospace & Energy Equipment:

-

Brazing of aircraft engine cooling channels and nuclear power plant cooling pipelines, withstanding high-temperature and high-pressure environments.

-

Solar thermal power high-temperature component connections, adapting to thermal cycling stresses.

-

-

Industrial Tools & Repair:

-

Brazing of carbide tools to steel substrates for balanced strength and heat resistance; repair welding of rolls and molds to extend service life.

-

-

Marine Engineering & Chemical Equipment:

-

Welding of seawater pumps, valves, and chemical reactors to resist corrosive media and high-pressure environments.

-

Packaging: Iron drums, plastic drums, plastic bags, cartons, pallets, custom packaging

Shape: Paste form, powder form, wire, rings.

Note: Melting temperature range 575-590°C; can be strengthened through modification and soaking treatments.

The aluminum-based brazing material 4045, with its low melting point, high wettability, and versatile forms, is widely used in automotive, electronics, aerospace, and other fields. In the future, through formula optimization (e.g., adding elements such as Ti and Cr) and process innovation, its potential in dissimilar material joining and precision manufacturing will be further unlocked.