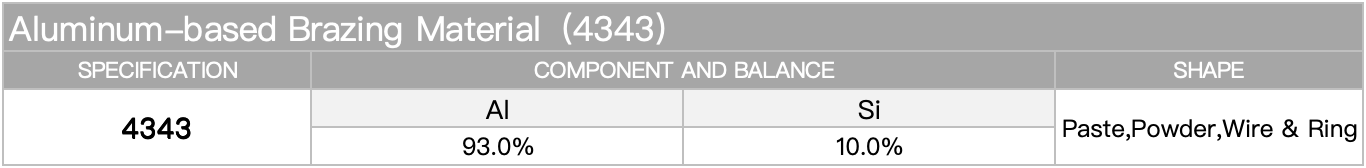

Aluminum-based solder 4343

Classification: 4343

International Designations:

-

AA 4343 (Aluminum Association standard, USA)

-

ISO 4343 (AlSi7.5) (International Organization for Standardization)

-

Chinese Standard: GB4A13 (LT13)

-

Other National Standards:

-

JIS A4343 (Japanese Industrial Standard)

-

UNS A94343 (Unified Numbering System, USA)

-

Product Features:

-

Low Melting Point & High Fluidity

-

Melting point: 577-582°C, narrow solidification range, excellent fluidity for filling complex joints, reducing porosity and crack defects.

-

Higher silicon content (6.8%-8.2%) compared to 4043 aluminum alloy (Si 4.5%-6.0%), further enhancing feeding capacity and suppressing weld cracks.

-

-

Corrosion Resistance & High-Temperature Stability

-

Aluminum-silicon alloy matrix resists oxidation and seawater corrosion, suitable for marine engineering and chemical equipment.

-

Softening temperature up to 900°C under high temperatures, maintaining stable mechanical properties.

-

-

Process Adaptability

-

Processable into sheets, welding wire, powder, etc., compatible with brazing, induction welding, laser sintering, and other techniques.

-

Commonly used as a cladding layer for composite brazing sheets (e.g., LQ2 brazing alloy sheets) with cladding thickness of 0.07-0.16 mm.

-

-

Welding Compatibility

-

Suitable for furnace brazing and flame brazing; requires flux (e.g., QJ206, QJ201) to optimize wettability and joint strength.

-

Applications:

-

Aerospace & Defense

-

Manufacturing of aircraft engine turbine components, structural components of Shenzhou spacecraft, and large aircraft composite brazing sheets, withstanding high-temperature and high-pressure environments.

-

-

Automotive & Refrigeration Industry

-

Brazing for automotive radiators and HVAC pipelines to ensure sealing and thermal efficiency; precision joining of refrigeration compressor parts to reduce leakage risks.

-

-

Electronics & Precision Instruments

-

Heat sink substrate welding for high-power electronic components (e.g., IGBT modules), improving thermal management.

-

Brazing for precision optical instrument brackets and aerospace fixtures, balancing lightweight design and strength.

-

-

Energy & Chemical Equipment

-

High-temperature brazing for nuclear power plant cooling pipelines and chemical reactors, resisting corrosive media and thermal cycling stresses.

-

-

Composite Brazing Sheet Manufacturing

-

Used as cladding material for LQ2 brazing sheets (base material: 3A21 aluminum alloy), widely applied in composite structure joining for ships, power equipment, etc.

-

Packaging: Iron drums, plastic drums, plastic bags, cartons, pallets, custom packaging

Shape: Paste form, powder form, wire, rings.

Note: Melting temperature range 575-615°C; can be strengthened through modification and soaking treatments.